Model No.︰RM500L

Brand Name︰RAINBOW

Country of Origin︰China

Unit Price︰US $ 41800 / pc

Minimum Order︰1 pc

500L brewery system, used for small brewery or pub.

♦ Brewhouse Unit

-Mainly used for preparing the wort.

-Brewhouse unit can be classified into 4 vesels: Mash tun, Lauter tun, Brew kettle, Whirlpool or combined to 2 vessels(Mash/Lauter tun, Brew kettle/Whirlpool or Mash/brew kettle, Lauter/whirlpool) / 3 vessels(Mash tun, Lauter tun, brew kettle/whirlpool).

Optional: hot liquor tank or cold water tank

|

Brewhouse System |

|

|

Outside wall |

SUS 304, thickness:2mm |

|

Inside wall |

SUS 304, thickness:3mm |

|

Insulation |

Polyurethane, thickness:100mm |

|

Polishing |

Inside mirror polishing to 0.4~0.6um without dead corner |

|

Welding |

100% TIG welding with pure argon gas shield |

|

Heating method |

Electricity/Steam/ Gas direct fire heating |

|

Top shape |

Dome top |

|

Bottom shape |

Cone bottom, 160 degree |

|

False bottom |

Removable, thickness:4mm, wedge type |

|

Top Manway |

Top manway with glass |

|

Side Manway |

Side manway for spent grains |

|

Sparging arm |

Removable |

|

Spraying ball |

CIP arm with 360° coverage CIP spraying ball |

|

Thermowell |

High accuracy temperature sensor: PT100 |

|

Plate heat exchanger |

SUS 304 plates and frame, working temperature: less than 150℃ |

|

Agitator |

Agitator with motor reducer, Power: 0.75kw, speed ratio:1:43 |

|

Legs |

Legs with height adjustasble pad |

♦ Fermentation Unit

-Mainly used for beer fermenting and maturing.

-Fementation unit usually includes beer fermenter, bright beer tank.

|

Fermentation System |

|

-Inside wall, SUS 304, thickness: 3mm; Outside wall, SUS 304, thickness: 2mm -Cooling jacket: both on cylinder and cone parts, SUS 304, thickness: 1.5mm -Insulation: Polyurethane, thickness:100mm -Inside polishing 0.4-0.6um without dead corner -100% TIG welding with pure argon gas shield -Dome top with dry hop port -Cone bottom, 60 degree -Top manway -Working pressure: 0.2Mpa -Test pressure: 0.3Mpa -Inside CIP arm with 360° coverage CIP spraying ball -Thermowell with high accuracy temperature sensor: PT100 -Pressure gauge -Safety/vacuum valve on top -Sample valve -Rotating racking arm on cone with butterfly valve -Discharge arm with butterfly valve -4 legs with height adjustable pad |

Optional:

-keg filling machine

-Keg washing machine

-Bottle filler and capper (4/6/8 heads)

-Filtering machine

-Labeling machine

-Boiler

-Beer keg (20L/30L/50L)

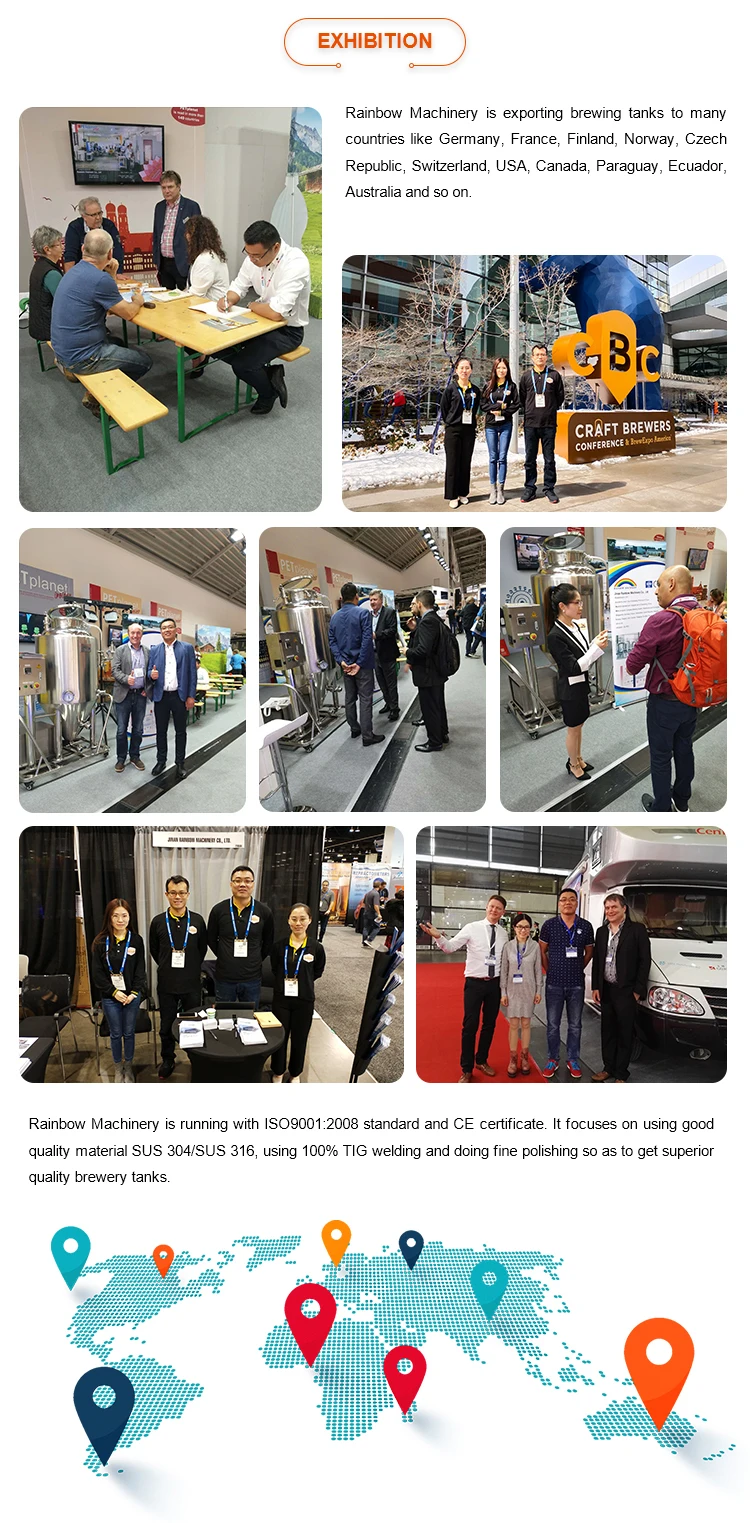

1) Jinan Rainbow Machinery Co., Ltd., is the most professional exporter and main manufacturer of craft beer brewery equipment for more than 8 years. Rainbow Machinery exports beer tanks to many countries, such as USA, France, Germany, Norway, Switzerland, Canada, Ecuador, Australia, Finland...

2) Rainbow Machinery can design and manufacture beer tanks as per customized request, which include tanks' capacity (100L-20000L), dimension (length, width, height), voltage (380v/220v/request), heating method (electricity, steam or gas fire)...

3) For control system, Rainbow Machinery insists on using famous electrical instruments brand, such as SIEMENS, DANFOSS, OMRON, SCHNEIDER, ABB...

4) Rainbow Machinery can ensure fine polishing for all tanks and 100% TIG welding with argon protection.

Payment Terms︰ T/T, L/C, Western Union