The configuration of brewery system:

Brewhouse system

2-Vessel: Mash/Lauter tun+Brew kettle/Whirlpool

Mash/Brew kettle+Lauter/Whirlpool

3-Vessel: Mash tun+Lauter tun+Brew kettle/Whirlpool

Mash/Brew kettle+Lauter tun+Whirlpool

4-Vessel: Mash tun+Lauter tun+Brew kettle+Whirlpool

Optional: Hot liquor tank or cold liquor tank

Specification of brewhouse:

-Exterior wall: SUS, 2mm; Interior wall: SUS, 3mm

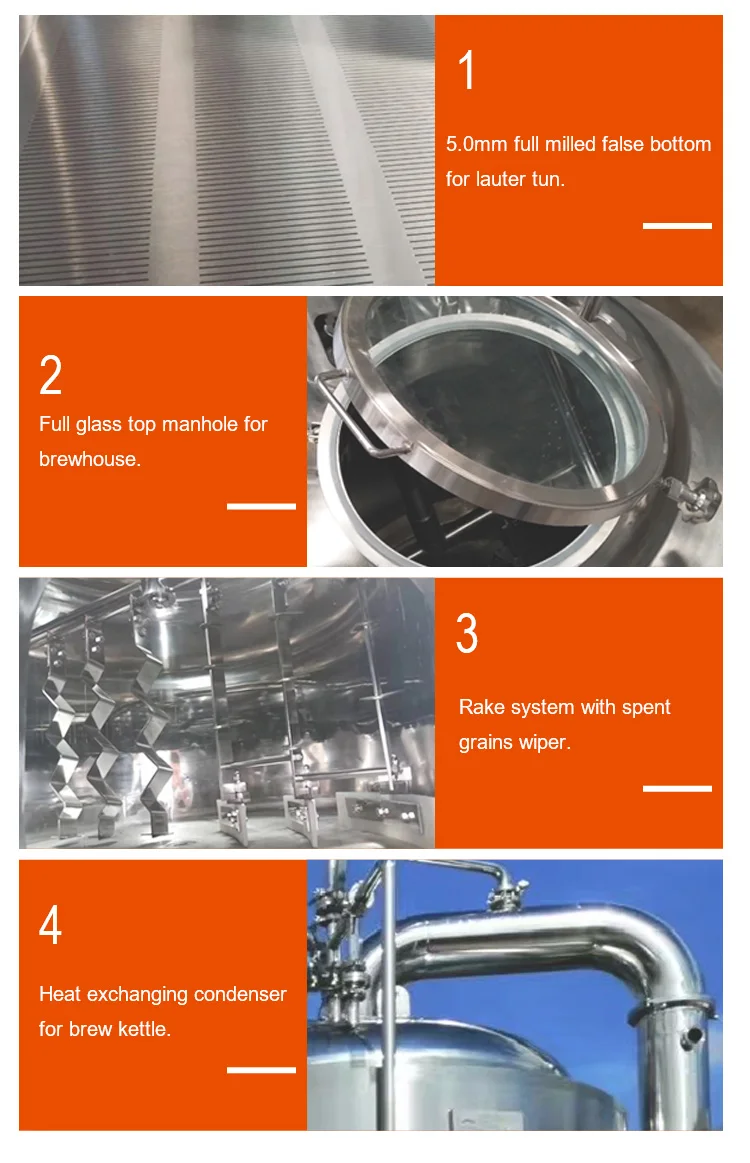

-Top mounted manway

-Side manway for spent grains

-False bottom for lauter tun, thickness: 5mm, wedge type, assemble and disassemble

-Tangential inlet for whirlpool

-Sparging arm for lauter tun

-VFD controlling for pumps and motors

-Automatic or semi-automatic control with pneumatic butterfly valves or electronic

-Thermowell with high accuracy temperature sensor: PT100

-4 support legs with height adjustable pad

-Level tube (optional)

-Grist case(optional)

-Grist hydrator (optional)

Fermentation system

-Fine polishing to 0.4um without dead corner

-SUS304/316 or red copper

-Cooling media: glycol water

-Dry hopping port on top

-Top/side manway

-Relief/vacuum valve on top, 3bar

-Sample valve

-Carbonation stone

-Bunging device

-Test Pressure:0.3Mpa

-Rotating racking arm

-4 support legs with height adjustable pad

-Complete valves, fittings and all parts

The 1000L complete brewing system for your reference:

|

Items

|

Equipment

|

Spec.

|

Qty.

(SET)

|

|

Brewhouse unit

|

Malt miller

|

300kg/h

|

1

|

|

Mash/Lauter tun

|

1000L

|

1

|

|

Brew kettle/Whirlpool

|

1000L

|

1

|

|

Hot liquor tank

|

2000L

|

1

|

|

Plate heat exchanger

|

10m2

|

1

|

|

Wort pump

|

3m³/h

|

2

|

|

Fermentation unit

|

Fermenter

|

1000L

|

6

|

|

Yeast adding tank

|

30L

|

1

|

|

Cooling unit

|

Glycol water tank

|

1500L

|

1

|

|

Glycol chiller

|

5hp

|

2

|

|

Glycol water pump

|

3m³/h

|

1

|

|

CIP unit

|

Alkali tank

|

100L

|

1

|

|

Sterilization tank

|

100L

|

1

|

|

CIP pump

|

3m³/h

|

1

|

|

Control unit

|

PID/PLC control panel

|

1

|

|

Spare parts

|

All necessary spare parts such as pipelines, valves, gauges and clamps…etc.

|